Laser wheel aligner for cars and vans

Technical information

Maximum axle load 2500 kg (max turntables load)

Maximum outer tyre diameter 830mm

Power supply: Battery operated 4 batteries 1.5 volt, size AA (Ø14x50 mm) in each measuring head

Lasers: Class II, max 1.2 mW

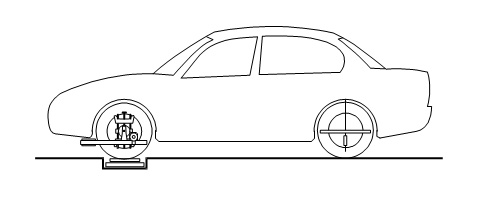

Laser wheel aligner GEOLUX is a device to measure all car wheel angle settings. Can be used in two versions, with 2 or 4 measuring heads. In both solutions is possible to measure all wheel settings necessary for perfect car road behaviour and optimal tyre wear.

Standard equipment:

- Measuring head left, 1 piece

- Measuring head right, 1 piece

- Self-centring wheel clamp for 12”-19” wheels, 2 pieces

- Centring scale with hangers, for 12”-19” wheels, 1 pair

- Steering wheel holder, 1 piece

- Brake pedal depressor, 1 piece

- Full floating turntable with scale 60°- 0°- 60°, maximum axle load 2500 kg, 2 pieces

- Operators manual, 1 piece

Measuring range:

| Total toe | : | –15 to +30 mm, -2° to +4° |

| Camber | : | -4° to +8° |

| Caster | : | -2° to +15° |

| King Pin incl. (SAI) | : | -2° to +15° |

| Front wheel Set-back | : | 0 to 50 mm |

| Turning angle | : | -60° to +60° |

Principle of operation

Car wheel alignment consist of measurement of horizontal and vertical angles.

The value of horizontal angles we reed directly from scales which are highlighted by beams coming from laser modules mounted in the measuring heads.

The values of vertical angles and wheel rotation is measured in electronic way and can be accesed directly from procector display. Optionally is possible also to observe them also on external PC or Android smartfon. Collection of all Caster/KPI results is done durind one Caster swing process.

Basic condition to get a precise readings is a confidence that pivot of a wheel clamp where we put on a head is exactly in an axis of wheel rotation. To get this we carefully make run-out procedure using wheel clamp compensators.

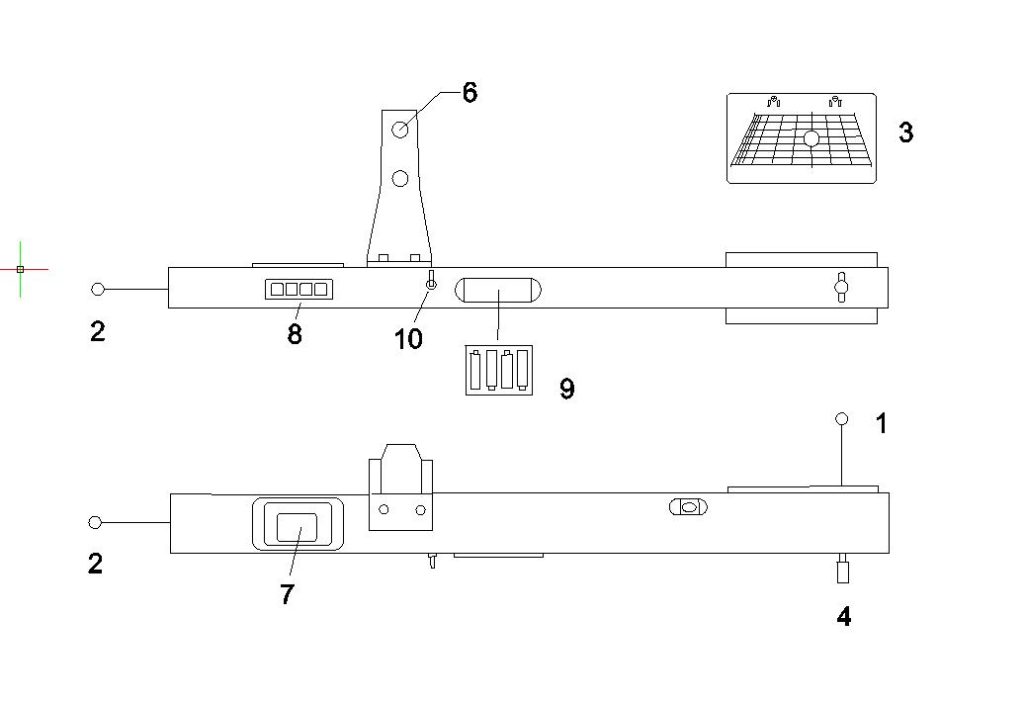

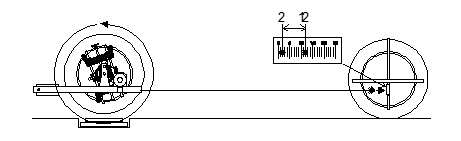

Structure of right projector

- Laser beam transverse. For measuring of Toe and Set-back

- Laser beam pointing rearward for reference front wheels to rear wheels

- Scale for Toe and Set-back

- Control lever for vertical adjustment of the transverse laser beam

- Spirit level for arm

- Adapter hole for attachment to the wheel clamp.

- Projector display.

- Keyboard.

- Battery holder with 4 batteries type AA -1.5 Volt (Ø14x50mm).

- On/off switch.

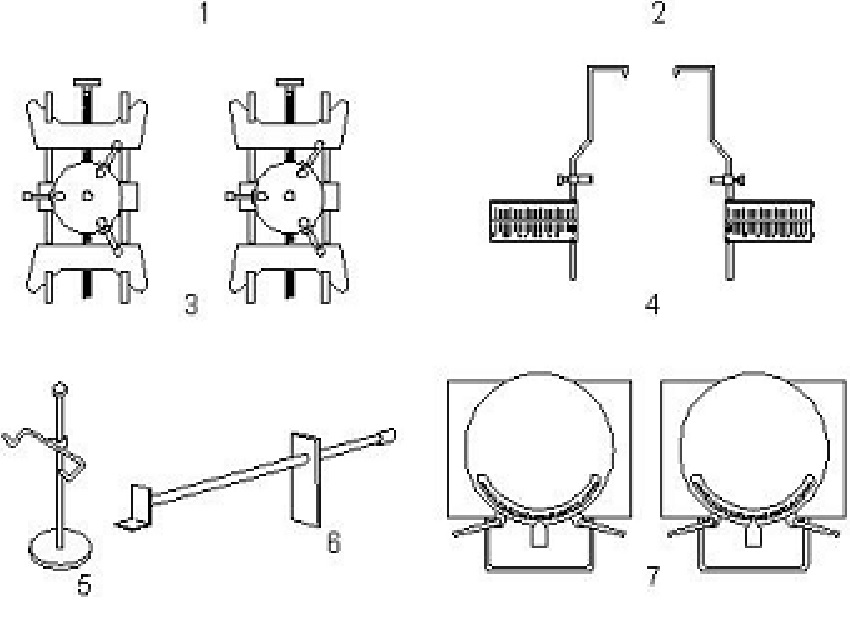

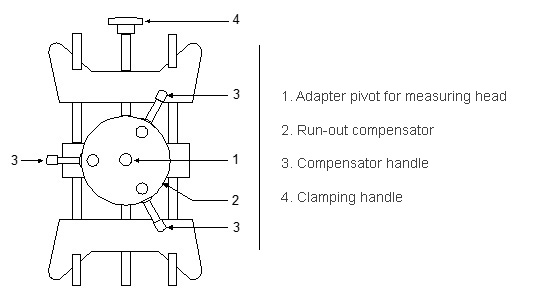

Wheel clamp with run-out compensator, self-centring

The jaws of the wheel clamp can be turned for clamping inside or outside on the rim.

Carry out of measurement

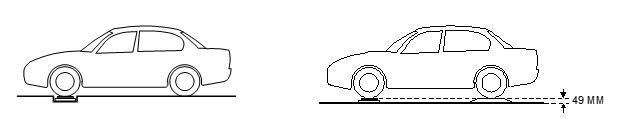

In order to assure correct wheel alignment, all wheels of the vehicle should be located on an area which is level in transverse and longitudinal direction.

The suspension, steering system and wheels should be serviced to normal condition prior to wheel alignment.

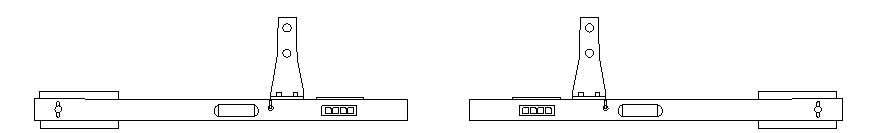

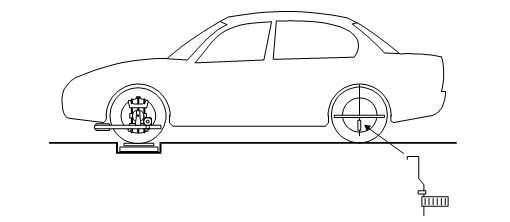

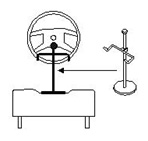

Attaching the wheel aligner

We attach clamps on a front wheels , scales on rear wheels and the measuring units on a clamp pivots.

To make sure of perfect pivot alignment with the wheel rotating axle we start a run-out procedure.

Therefore we rise a front of a car

And rotate a wheel observing a laser spot on a rear scale

If the spot is moving aside of center value we perform run-out procedure.

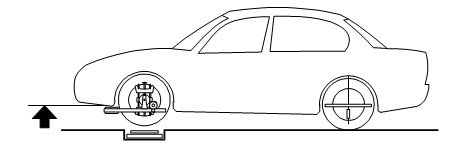

After this, laser beam doesn’t move aside and stays in the center.

Afterward we lower the car and apply brake pedal depressor and steering wheel lock

(after setting in a center position)

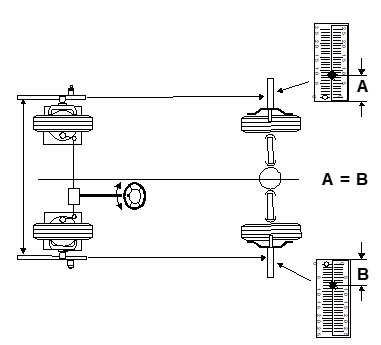

Front axle measurement

After previous preparations we are ready to read angle values of front axle, assuming that rear axle thrust angle is close to zero.

Front wheels should be steered until the readings on left and right scale at the rear wheels are the same

(A = B).

The front wheels are now in straight ahead position.

Now we can directly read toe and camber values. In most cases is enough. In case to obtain caster and KPI we have to steer front wheels 100 or 200 to the left and right.

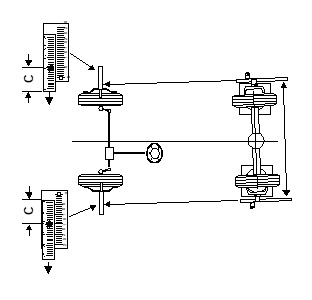

If we want to take care abort four wheels we have to start from the rear axle.

Thanks of device construction rear axle trust angle is taken into consideration while measuring front toe.

As a result we obtain all necessary values readings and regulations we need for a perfect car driving on a road.